Look inside every cell without opening a single one

The Role of INNER’s CT/X-Ray technology within the EV Testing Market

How does INNer optimize the ev battery testing process?

We optimize the EV battery testing process through our non-invasive CT/X-Ray scanning which entails:

Revealing hidden physical faults in the cells and preventing EV battery failures before they happen.

Providing a quicker and more accurate assessment of what we like to call the battery’s “State of Integrity”: leakages, cracks, swelling, tears and a wide variety of physical deformations inside and between cells.

Meticulously detecting faults down to 50 micron.

No guesswork. We are confident in every cell.

All of this, without disassembling the EV battery pack.

whether it is a new or a used pack

we can help you detect issues such as:

Torn wires

Swelling of cells

Cracks

And many more!

stacking of cells

Our End-to-End Solution

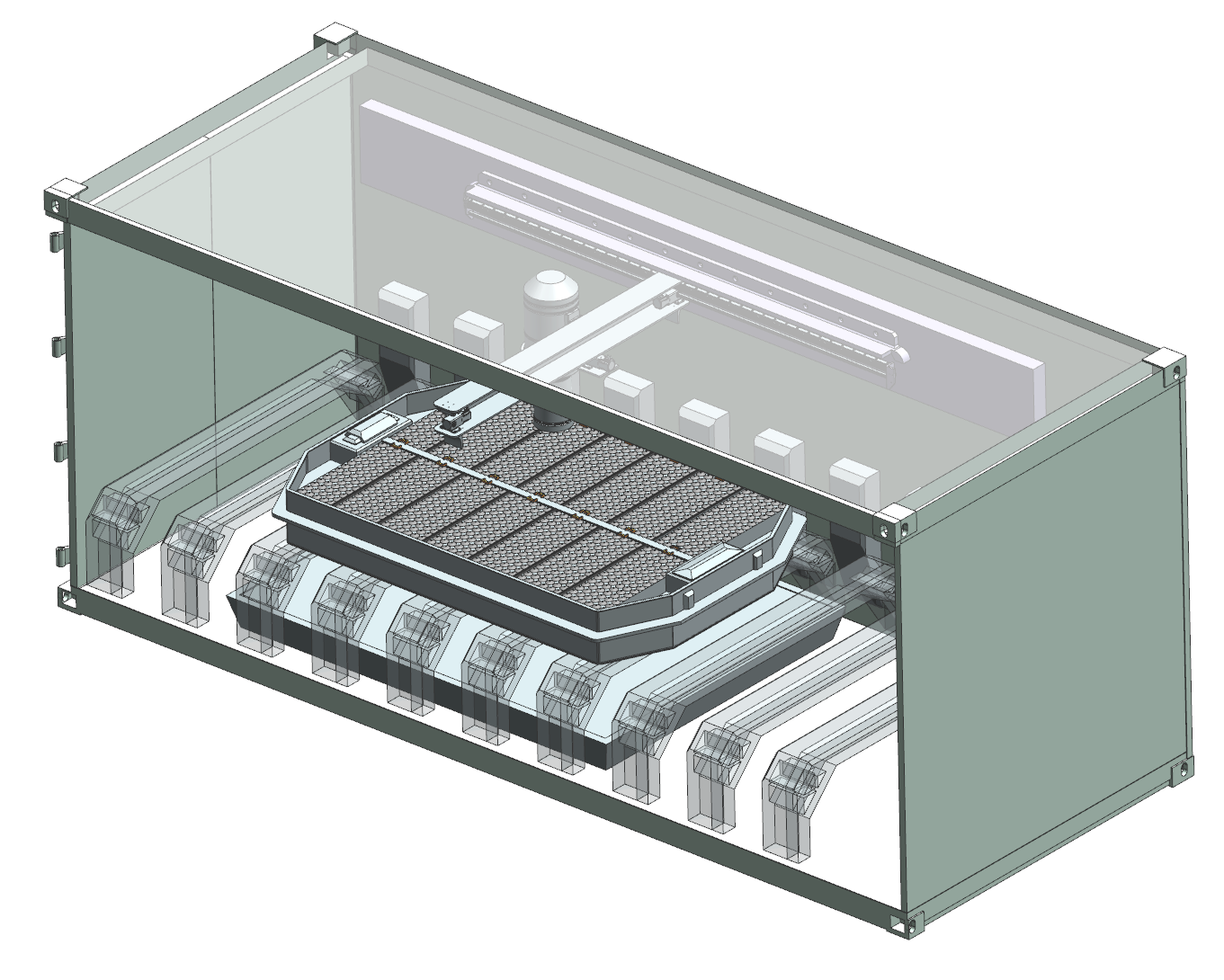

Pack Scanner

(Coming soon)

Module Scanner

(Coming soon)

Service offering

Available now! (Beta version)

This is a combined hardware and software to offer complete diagnosis and deliver an actionable report within minutes.

Detect. Analyze. Take control.

Our non-invasive X-Ray/CT technology allows us to create a visual and easy-to-understand actionable report that includes everything that went wrong inside the tested pack, including its exact measurements and location.

The output outlines recommended uses, safety considerations, and options for repair or reuse which allows you to take immediate and effective action.

The CT scanning integrated with machine learning analysis meticulously detects faults down to 50 micron, ensuring accuracy and efficiency. Our end-to-end scanning takes only a few minutes which results in a higher amount of battery packs that can be tested and analysed.

With our solution we provide a rapid, precise, diagnosis of a wide range of physical faults, pinpointing their exact location.

Our CT scanner is able to detect faults from the outside which means no need to disassemble the battery or utilise a Battery Management System (BMS). Depending upon the results of the scan, you can decide whether to perform SoH, SoC or any other type of electrical testing.

Additionally, we support any type of cell chemistry and formation, existing and future alike. Meaning, you will not be limited in testing.

What we offer:

Safety

We ensure safety during the testing process by preventing failures before they happen.

accuracy

Our CT/X-ray technology accurately identifies faults down to 50 micron.

Speed

Fast, automated inspection that fits seamlessly into high-throughput production lines.

nondestructive testing (NDT)

Get full visibility of what is going on inside your batteries you process without the need of cutting, opening, or destroying them.