We make the invisible visible.

x-ray is the way!

For decades, X-Ray has been the best solution to look inside any matter;

For instance, it has been used in a variety of industrial applications, where long term quality performance is required, with the most prominent example being high-end chip manufacturing; In recent years, it started being used in Gigafactories battery cell production quality inspection.

Nevertheless, so far - it was never used commercially in quality inspection of complete battery packs; The reason for that was that the existing X-Ray pack scanners were research oriented: they were designed to scan samples; It took too long to scan a single battery pack; therefore, they were not a good fit to the commercial workflow.

Our solution can deliver an output within minutes by optimizing analysis with throughput and workflow.

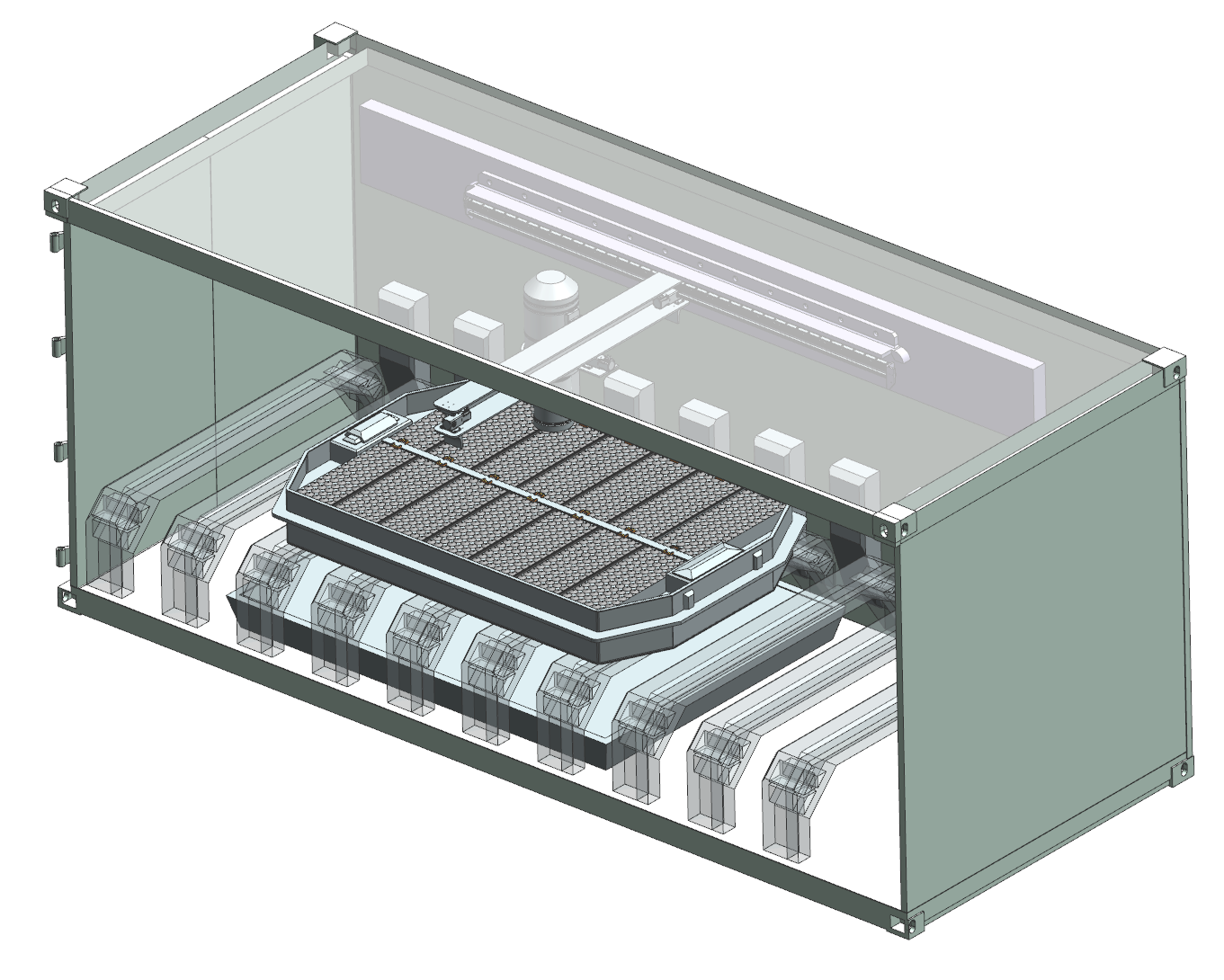

Pack Scanner

Precise and fast fault analysis without the need of disassembling the pack

Coming soon

Module Scanner

Quicker and more accurate assessment of what we like to call the battery’s “State of Integrity”: leakages, cracks, swelling, tears and more

Coming soon

Service Offering

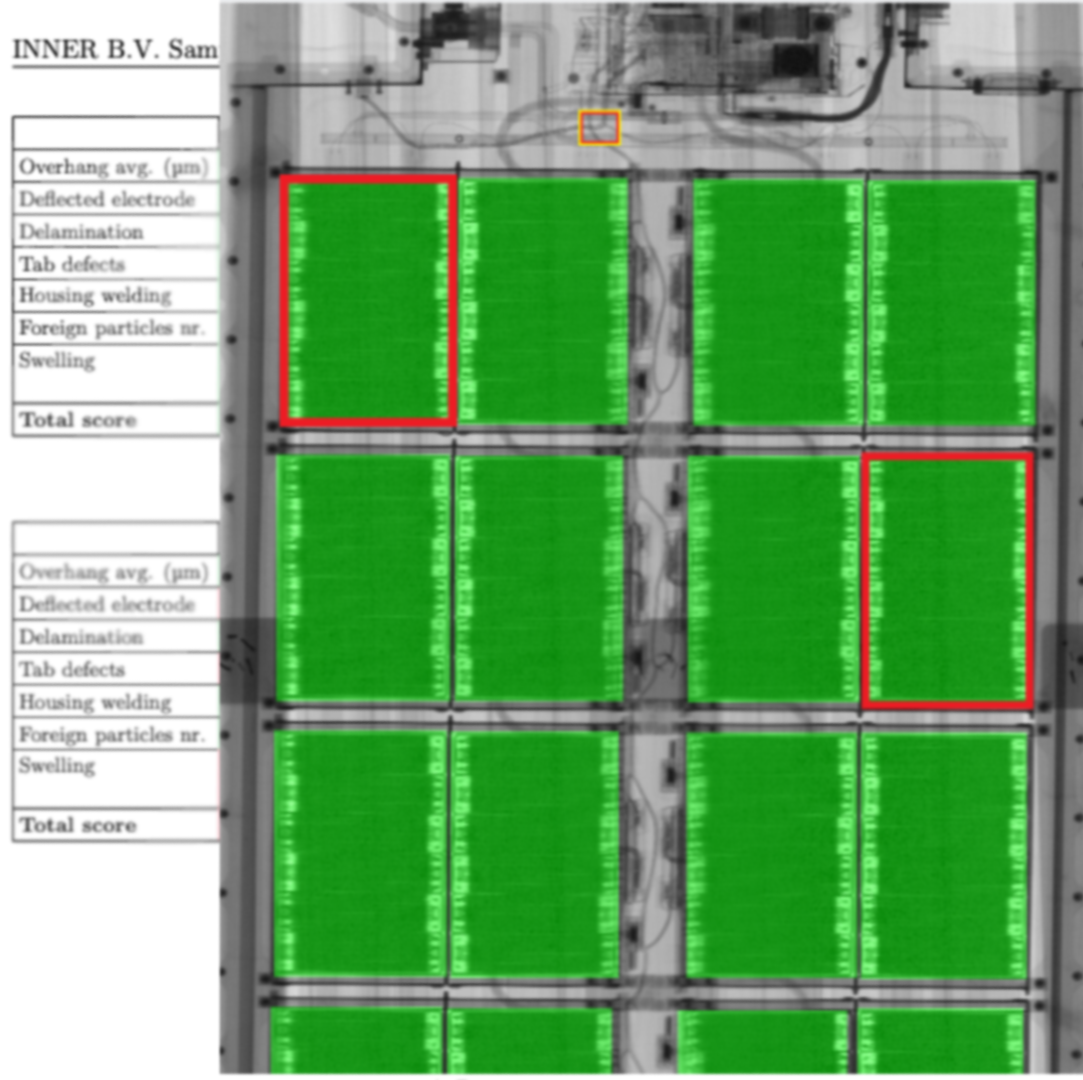

We provide a visual and easy-to-understand actionable report that includes everything that went wrong inside the tested pack

Available now!

(Beta Version)

An End-to-end solution

We combine our own patented hardware and proprietary software to offer complete diagnosis; The output is an actionable report, in your hands, within minutes, advising you exactly how to proceed;

The CT scanning integrated with machine-learning analysis meticulously detects a wide variety of faults down to 50 micron, ensuring accuracy and efficiency. Our end-to-end scanning takes only a few minutes which results in a higher amount of battery packs that can be tested and analyzed.

Our goal is the automating, standardization, growth and scaling of our customers;

-

Leveraging our X-ray computed tomography system we provide an end-to-end actionable diagnosis at the end of the pack assembly line to improve quality assurance processes and detect:

Tears

Misalignments

Structural anomalies

All without dismantling the battery pack.

-

Our technology provides cell producers access to the largest global database of EV battery cells and packs field gathered image analysis - taken from the battery pack level.

This enables for a unique, long term ongoing tracking and monitoring analysis of the cells and modules to identify unknown patterns: uniformity, positioning of internal components, degradation and irregularities to facilitate improvement of the cell and pack design.

-

Leveraging our X-ray computed tomography system, we provide you with an end-to-end actionable diagnosis of the battery pack to improve quality assurance processes and detect:

Tears in wiring

Misalignments

Structural anomalies

All without dismantling the battery pack.

Our CT scan and AI analysis system is crucial for BESS builders repurposing EV batteries.

It provides detailed internal imaging of complete battery packs, detecting structural anomalies or hidden defects. This ensures only safe, structurally sound batteries are integrated into second-life storage systems, enhancing reliability and safety at the gate

-

By detecting potential hazards within batteries, such as internal damage or thermal runaway risks, our technology helps recyclers implement targeted safety protocols, reducing the risk of fires during the recycling process.

Leveraging our system, recyclers can easily visualize the internal setting and formation of the modules and all of the other components of the pack, without opening it.

Why choose INNER?

The only ones offering a Commodity Approach

Larger detector high throughput

(x20) designed for battery packs

the only ct producing a report in minutes

Available now:

Send us your packs for diagnosis!

Our team will be happy to have a conversation to better understand the quality issue you are concerned about. Then, we will await to receive the packs and analyze what we see; Any abnormalities will be flagged in an actionable report - no need to interpret images - our software does that for you.

Just fill out your details in the form and we will be in contact with you as soon as possible!

Don't leave your battery reliability to chance - contact us today and take advantage of our beta testing services offered in collaboration with Fraunhofer EZRT.

Or

Book a Demo

Schedule your demo now and take the first step towards a safer, more profitable and sustainable world.