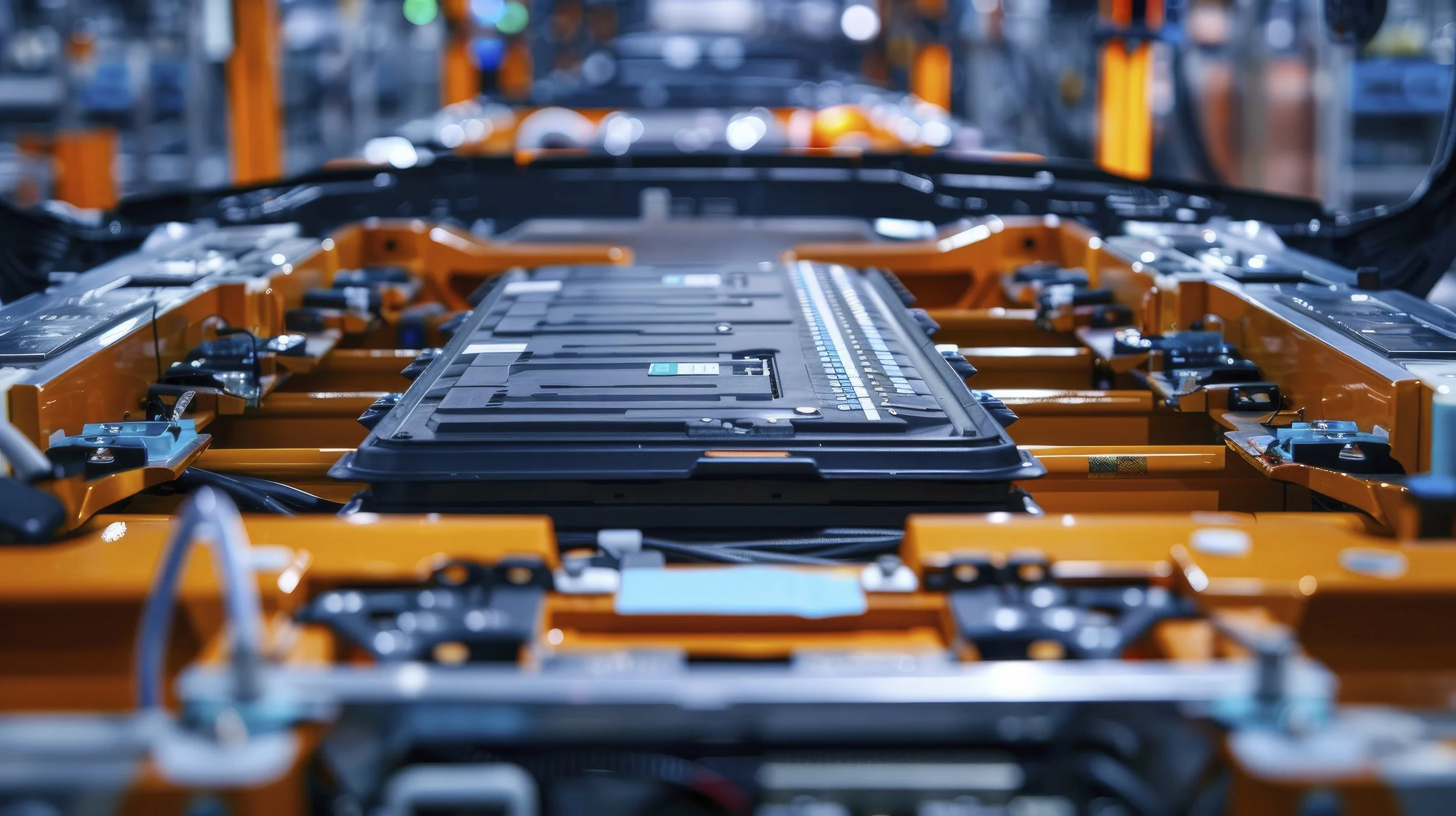

Our X-Ray/CT Scanner

An end-to-end solution designed to fit the high-paced pack assembly process.

-

We designed a Computed Tomography (CT) scanner integrated with machine-learning analysis to meticulously detect a wide variety of internal faults (torn wires, leakages, swollen cells and more) down to 50 micron, ensuring accuracy and efficiency.

INNER’s X-Ray/CT scanner is the only one designed in a commodity approach - first to be an integral part of the end of line quality inspection; as well as in quality inspection and repair in later stages throughout the EV battery lifecycle; from remanufacturing to assembling to repurposing.

-

Outside dimensions: 20ft container

Capacity (packs/h): 8 packs

Scan time (min): 5 min

Processing time (min): 5 min

Power consumption (kW): 3

-

We provide our partner with a complete diagnostics of their battery packs by determining their State of Integrity which refers to a wide range of physical faults that can be found inside and between cells and modules of the battery pack. Examples of these faults are: torn wires, swelling cells, cracks and leakages and many more.

Our end-to-end scanning takes only a few minutes which results in a higher amount of battery packs that can be tested and analyzed - to fit the workflow and high throughput of our partners.

Furthermore, the combination of our own patented hardware and proprietary software offers complete diagnosis; The output is a simple to follow actionable report, in your hands, within minutes, advising you exactly how to proceed.

Precise.

Accurately identifying internal physical faults down to 50 micron.

FAST.

Rapid diagnosis within minutes to fit with your workflow.

nondestructive.

Full visibility inside battery packs without the need for disassembling.